Why are more and more brands choosing to work directly with shapewear source factories?

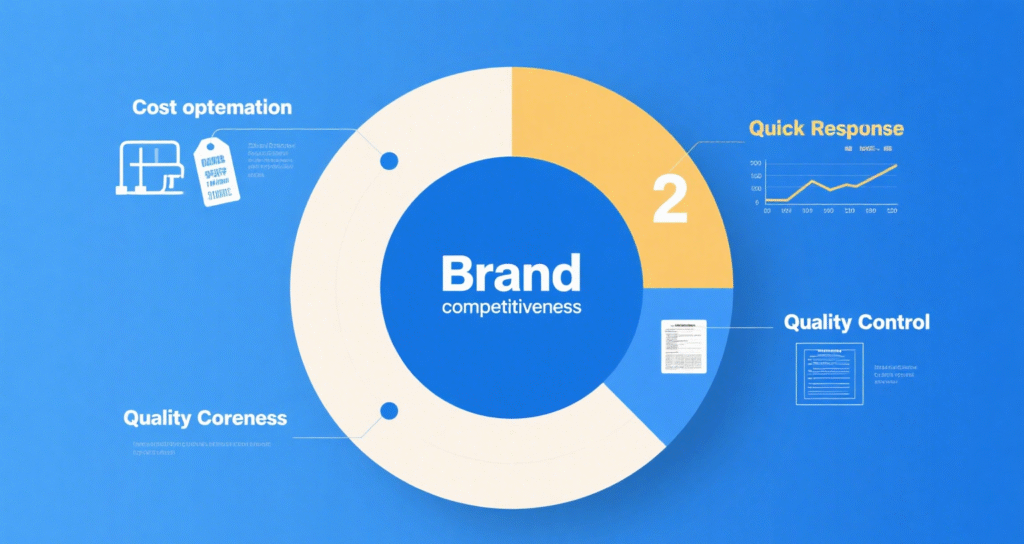

This article will delve into the 3 core advantages behind this trend, revealing why directly collaborating with shapewear source factories has become a key choice for brands to reduce costs, improve efficiency, and enhance competitiveness.

Table of content

| 1. Cost Advantage: Eliminating Middlemen to Achieve “Price Control” and “Profit Enhancement” |

| 2. Production flexibility: Rapidly respond to market demands and shorten the “from design to market launch” cycle |

| 3. Quality Control: Controlling Production Standards from the Source to Reduce “Quality Control Risks” |

In the shapewear industry’s supply chain system, the collaboration model between brands and suppliers is quietly undergoing a transformation. In the past, many brands were accustomed to connecting with production through intermediaries, traders, or agents. However, in recent years, an increasing number of shapewear brands—whether emerging niche brands or established chain brands—have begun to opt for direct collaboration with source factories. This shift is not accidental but stems from the irreplaceable core value that source factories can bring to brands. This article will delve into the 3 core advantages behind this trend, revealing why directly collaborating with shapewear source factories has become a key choice for brands to reduce costs, improve efficiency, and enhance competitiveness.

Cost Advantage: Eliminating Middlemen to Achieve “Price Control” and “Profit Enhancement”

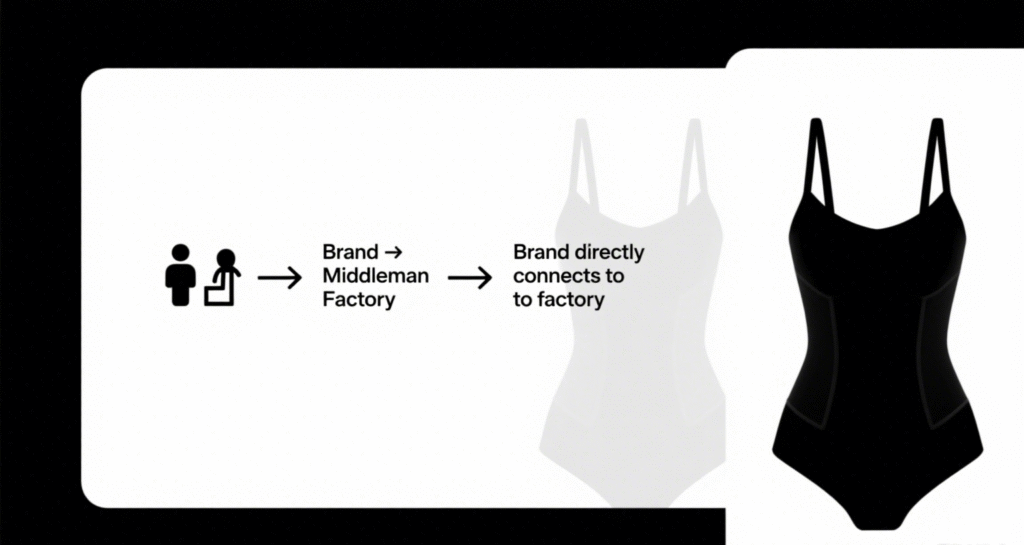

For brands, cost control directly impacts pricing strategies and market competitiveness, and source factories hold a significant advantage in terms of cost.

In the traditional model, when brands place orders through intermediaries, each layer adds operational costs, channel profits, and communication costs, ultimately leading to high procurement prices for brands. For example, a shapewear garment with a factory price of $10 may rise to $15–20 after passing through traders and agents, significantly compressing the brand’s profit margin.

By directly connecting with source factories, brands can bypass all intermediaries and procure directly at “factory prices,” reducing procurement costs by 20%-30%. More importantly, source factories provide transparent cost breakdowns—from fabric procurement, production costs, to labor expenses—allowing brands to clearly understand cost structures and adjust product configurations based on market positioning.

Production flexibility: Rapidly respond to market demands and shorten the “from design to market launch” cycle

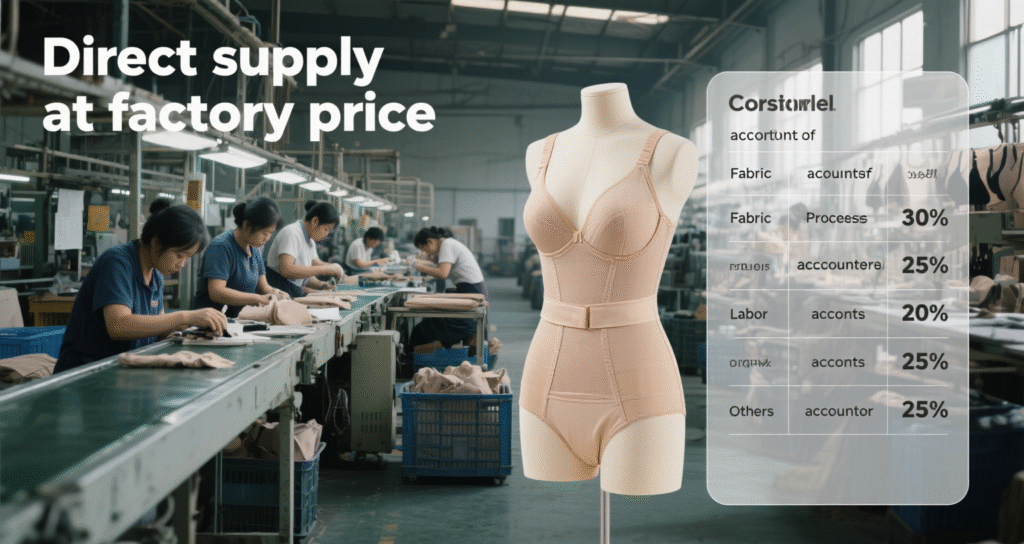

Trends in the shapewear industry change extremely quickly—from styles to consumer preferences, the pace of iteration far exceeds expectations. This places extremely high demands on a brand’s supply chain responsiveness, and the production flexibility advantages of source factories become critical.

First, shorter sample production cycles. When directly collaborating with factories, brands can convey design drawings, fabric requirements, and production details directly to the factory’s R&D team, eliminating the time lost through intermediaries. Most source factories can achieve “72-hour rapid prototyping,” while using intermediaries may take 7–10 days. For brands needing to test market feedback, improved prototyping efficiency means faster validation of product feasibility, avoiding missed trend windows.

Second, orders are more flexible. Source factories can support a “small-batch trial production + bulk reorder” model: brands can first test the market with a small order of 500-1,000 pieces. If sales meet expectations, the factory can complete bulk production of tens of thousands of pieces within 1-2 weeks without needing to re-adjust the production line. This flexibility is particularly important for emerging brands—it reduces the financial risk of initial inventory while enabling them to quickly capitalize on viral product opportunities.

Finally, stronger customization capabilities. Source factories have complete production lines and R&D teams, enabling them to provide deep customization based on brands’ personalized needs. For example, for the demand for plus-size shapewear in the European and American markets, the factory can adjust the pattern and cutting; for collaborations with sports brands, it can develop “high-elasticity + moisture-wicking” composite fabrics; and it can even design custom embroidery and printing processes based on the brand’s logo. This “on-demand customization” capability allows brands to quickly launch differentiated products and avoid falling into homogenized competition.

Quality Control: Controlling Production Standards from the Source to Reduce “Quality Control Risks”

As a functional product worn close to the body, the quality of shapewear directly impacts a brand’s reputation—whether the fabric causes allergies, whether the elasticity is durable, whether the seams are secure—any detail issue could lead to returns, negative reviews, or even a crisis of brand trust. By directly collaborating with source factories, brands can achieve deep control over quality from the production source.

On one hand, raw materials and production processes are traceable. Source factories establish long-term partnerships with fabric suppliers, providing comprehensive raw material quality inspection reports to ensure compliance with the brand’s target market standards. Brands can even conduct on-site inspections of the factory’s raw material warehouses and production facilities to verify storage conditions and production environments, thereby preventing the risk of substandard materials being used.

On the other hand, quality control is integrated throughout the entire process. Source factories support brands in participating in quality inspections at every stage of production: from pre-production sample confirmation, to inspections during the production process, to batch sampling before shipment. This “transparent” quality control model allows brands to promptly identify issues and request adjustments, preventing large quantities of non-conforming products from entering the market.

In the increasingly competitive shapewear market, a brand’s core competitiveness stems not only from design and marketing but also from the efficiency and resilience of its supply chain. By directly connecting with source factories, brands essentially “extend their supply chain upstream,” leveraging cost optimization, rapid response capabilities, and quality control to build differentiated competitive barriers.

For emerging brands, this translates to lower startup costs and faster market testing opportunities; for established brands, it means more stable quality, higher profit margins, and greater flexibility in responding to market changes. Therefore, selecting a shapewear source factory with R&D capabilities, production scale, and quality control expertise has become a critical strategy for brands to establish a foothold in the industry and achieve sustained growth.