“Seamless” vs. “traditional splicing”: Which shapewear manufacturing process is better suited to your procurement needs?

This article will provide an in-depth analysis from technical principles, performance characteristics to applicable scenarios, offering procurement professionals a clear guide for selection.

Table of content

| 1. “Seamless” Technology: An Innovative Process Prioritizing Comfort |

| 2. Traditional Seamless Construction: A Classic Solution Focused on Shaping |

| 3. Procurement Decision Guide: Starting from Core Requirements |

| 4. Our Production Capacity: Dual-Process Full-Chain Assurance |

In shapewear procurement decisions, the choice of manufacturing process directly impacts product competitiveness. Currently, the mainstream “seamless” (one-piece molding) technology and traditional seam-based processes each have their own advantages and disadvantages. Understanding the core differences between the two is essential for accurately matching procurement needs. This article will provide an in-depth analysis from technical principles, performance characteristics to applicable scenarios, offering procurement professionals a clear guide for selection.

1. “Seamless” Technology: An Innovative Process Prioritizing Comfort

Seamless technology originated from the seamless weaving revolution in the textile industry. Its core principle involves using special circular looms to directly weave yarn into tubular fabric resembling the human body’s shape, followed by minimal processes such as cutting and hemming to complete the garment. Throughout the production process, the main body of the garment requires no needle-and-thread assembly, with only minimal seams retained at details like the collar and cuffs.

The core advantages of this process are concentrated in the wearing experience:

• Zero-friction comfort: Eliminates the friction and irritation caused by traditional seams on the skin, making it particularly suitable for sensitive skin or prolonged wear scenarios, such as daily commuting or pregnancy shaping.

• Enhanced fit: During the weaving process, the density of the yarn can be adjusted to achieve localized elasticity changes, allowing the garment to naturally stretch with body movements and avoid the “tight, constricting sensation” of traditional shapewear.

• Lightweight design: The fabric structure achieved through one-piece knitting is lighter and thinner, maintaining breathability and preventing stuffiness even in summer, aligning with contemporary consumers’ demand for “invisible shaping.”

However, the “Seamless” technology also has limitations:

• Shaping strength is limited by the process, making it more suitable for users seeking mild shaping and daily maintenance. It lacks sufficient support for heavy-duty shaping needs (such as postpartum recovery).

•The design is relatively simple, unable to achieve multi-material splicing or three-dimensional cutting, resulting in relatively monotonous styles.

2. Traditional Seamless Construction: A Classic Solution Focused on Shaping

Traditional seamless construction involves cutting multiple pieces of fabric and sewing them together with needles and thread to create finished garments. This is a mature technology in the shapewear industry. Its core logic is to use ergonomics to sew different functional fabrics together at specific locations, using the tension of the seams to enhance the shaping effect.

The core advantages of this process lie in its functionality:

• Strong shaping capability: The “pressure gradient” formed by multi-piece assembly can precisely tighten the waist and abdomen, lift the buttocks, and reduce side breasts, making it suitable for scenarios with specific shaping requirements, such as wedding dress matching and postpartum recovery.

• High design flexibility: It can achieve multi-material combinations, three-dimensional cutting, and complex decorations (such as lace and embroidery), meeting diverse aesthetic needs.

• Enhanced durability: Reinforced stitching ensures the garment maintains its shape even after repeated stretching, with a lifespan generally longer than one-piece molded products.

The primary drawback of traditional craftsmanship lies in wearing comfort:

• Seams may cause pressure marks, particularly under tight-fitting garments, affecting aesthetics.

• Multi-panel construction results in thicker fabric with poorer breathability, reducing comfort during summer wear.

3. Procurement Decision Guide: Starting from Core Requirements

1. Cost Comparison

• One-piece molding process: High equipment investment but high single-piece production efficiency, suitable for large-scale mass production, with a unit price of approximately 30–80 yuan.

• Traditional piecing process: Low equipment barriers, but relies on manual sewing, resulting in high mass production costs, with a unit price of approximately 50–150 yuan, and complex designs can exceed 200 yuan.

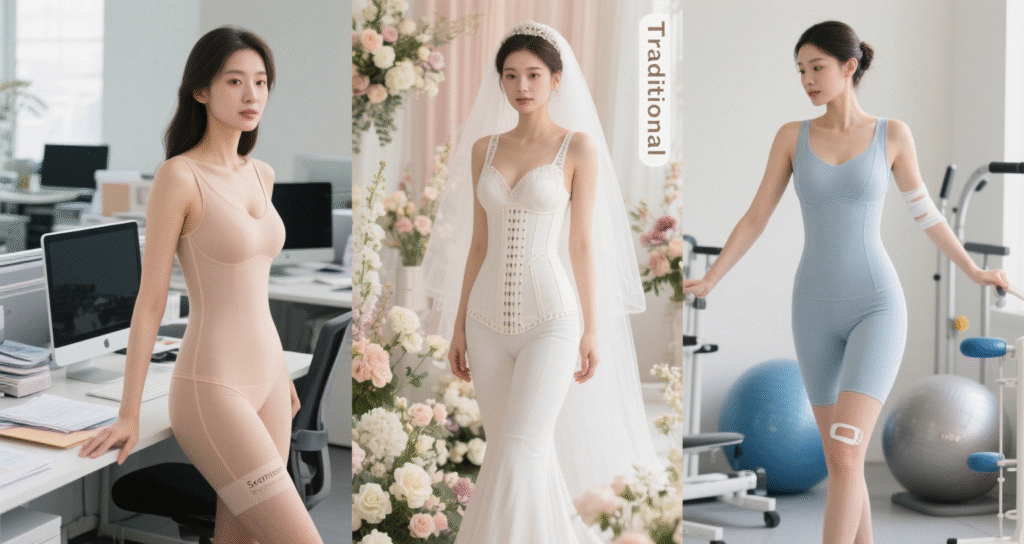

2. Customer Segmentation

• Young consumer group: Prioritizes comfort and everyday styling, with one-piece molding process designs being more appealing.

• Mature women: Demand high shaping effects and are more receptive to functional products made with traditional processes, particularly emphasizing detailed design.

• Special needs groups: Should prioritize traditional seam-stitching process options with strong shaping effects.

3. Scenario Adaptation

• Daily commuting, fitness, and exercise: Recommended one-piece molding process, balancing comfort and mild shaping.

•Special occasions (weddings, banquets): Traditional seam-sewn high-waisted shapewear better creates a perfect silhouette.

•Post-surgery recovery, long-term shaping: Medical-grade shapewear using traditional craftsmanship must be selected to ensure sufficient support.

4. Our Production Capacity: Dual-Process Full-Chain Assurance

As a shapewear manufacturer with 12 years of experience, we have established a flexible production system that integrates dual processes to meet diverse procurement needs. We have over 5,000 square meters of modern factory space and dozens of advanced electronic jacquard underwear machines.

We have a complete and scientific quality management system, ensuring stable and exceptional quality to meet the needs of different consumers. Our team responds quickly and can swiftly adapt to customer requirements. Daily production capacity reaches 10,000 pieces, fully meeting the production needs of various clothing orders.

There is no such thing as an absolutely optimal process; only the most suitable choice for your needs. One-piece molding technology strikes a balance between comfort and efficiency, while traditional splicing technology combines shaping and design. By clearly defining product positioning, customer characteristics, and application scenarios, you can make precise decisions. Our dual-process production capabilities will provide flexible and tailored solutions for your procurement needs. Please feel free to contact us for customized quotes and sample testing.