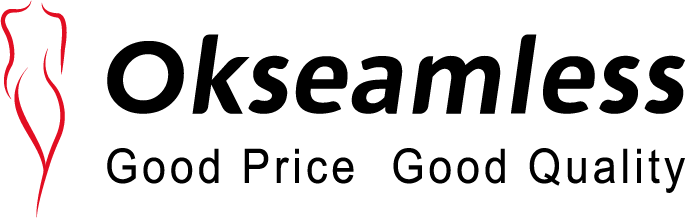

OEM vs ODM: Which cooperation model is suitable for your shapewear brand?

This article will clearly explain the differences between the two, analyze their respective advantages and disadvantages, and provide tailored recommendations based on your specific circumstances.

Table of content

| Core Differences Between OEM and ODM |

| Analysis of the Advantages and Disadvantages of the Two Models |

| How to Choose a Cooperation Model Based on Your Own Situation |

| Our company’s professional capabilities |

In the highly competitive shapewear industry, choosing the right production cooperation model is a critical step for brand success. As two mainstream cooperation models, OEM and ODM often leave buyers torn. This article will clearly explain the differences between the two, analyze their respective advantages and disadvantages, and provide tailored recommendations based on your specific circumstances. We will also introduce our company’s professional capabilities under both models to help you find the most suitable collaboration approach for your brand.

Core Differences Between OEM and ODM

OEM (Original Equipment Manufacturer)

OEM stands for Original Equipment Manufacturer. In the shapewear industry, it refers to the situation where the buyer owns their own product design plans, technical specifications, and brand logos, and the collaborating factory produces the products according to these specific requirements. In simple terms, it means “I design, you produce.” The buyer has full control over the product design, fabric selection, and production details, while the factory is solely responsible for completing the production process according to the established standards.

ODM (Original Design Manufacturer)

In this model, the factory not only handles production but also provides a one-stop service from product design and R&D to manufacturing. The buyer can either select an existing design from the factory or make minor adjustments to the factory’s design, ultimately applying their own brand label. In other words, “you design, you produce, I label.” In this model, the factory’s design capabilities and R&D strength play a crucial role.

Analysis of the Advantages and Disadvantages of the Two Models

Advantages and Disadvantages of the ODM Model

Advantages:

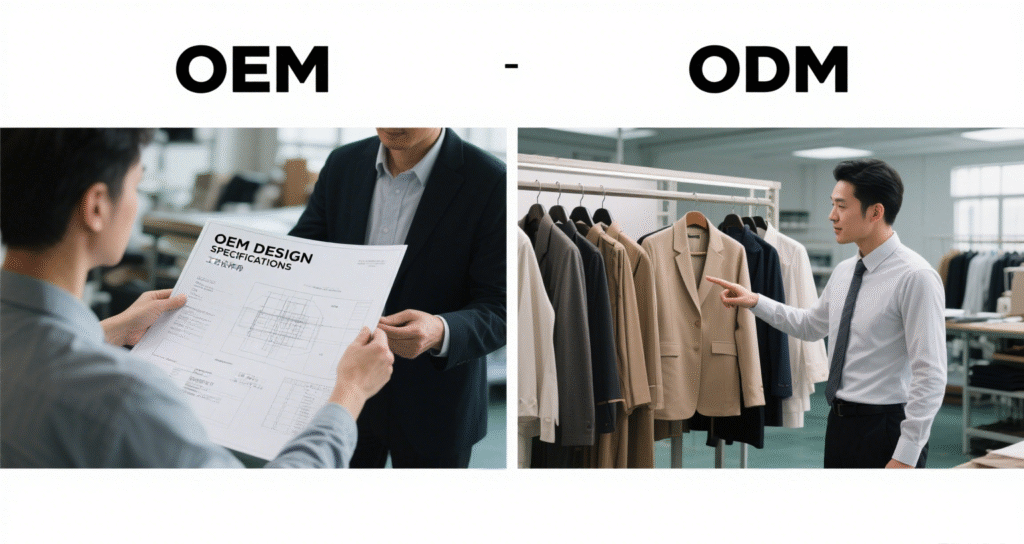

• Convenient and Efficient: For buyers lacking their own design teams, the ODM model eliminates the need for the cumbersome processes of product design and R&D, allowing them to directly utilize the factory’s established design solutions, significantly reducing the time from concept to market launch.

• Cost-Effective: There is no need to invest heavily in establishing an in-house design team and R&D system, effectively reducing initial labor, material, and time costs, making it particularly suitable for startups or companies with limited budgets.

Disadvantages:

• Risk of product homogenization: Since design solutions originate from the factory, they may be adopted by multiple brands, leading to homogenized products in the market, which is unfavorable for brands to establish unique competitive advantages.

• Low design autonomy: Purchasers have limited involvement in product design, making it difficult to fully customize designs according to their brand philosophy and market positioning, which may restrict the brand’s long-term development.

Advantages and disadvantages of the OEM model

Advantages:

• Strong product uniqueness: Purchasers can design products independently based on their brand positioning, target customer groups, and market demands, making the products unique and better able to meet consumers’ personalized needs, thereby standing out in market competition.

• Prominent brand identity: Products designed independently can fully reflect the brand’s core values and cultural connotations, helping to enhance brand recognition and reputation and increase the brand’s influence in the market.

Disadvantages:

• High initial investment: It requires establishing a professional design team and conducting product R&D and testing, which involves significant upfront financial and time investments, placing high demands on the company’s capabilities.

• Long cycle time: From product design, prototyping to final production, the entire process is relatively lengthy, potentially missing the optimal market timing.

How to Choose a Cooperation Model Based on Your Own Situation

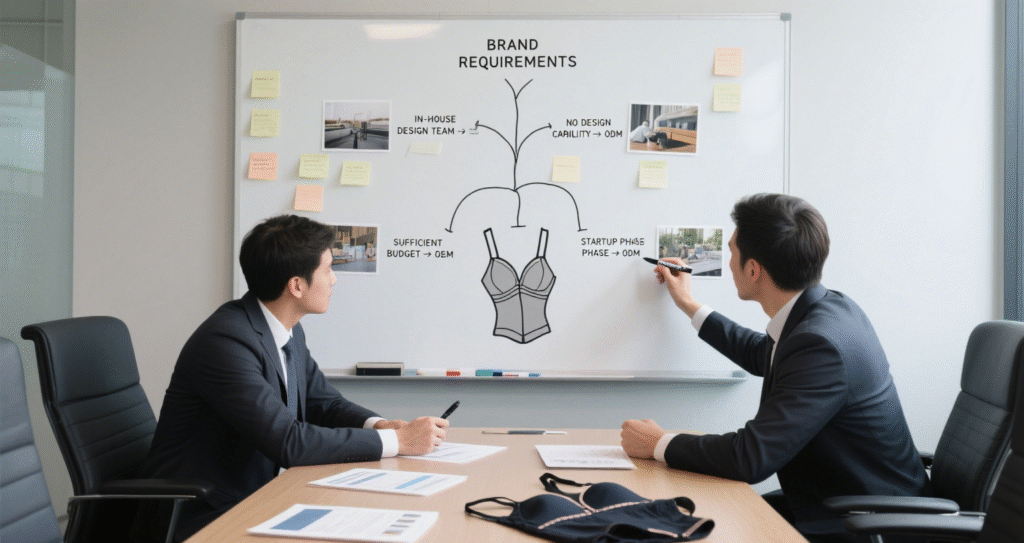

Based on Your Own Strengths (Whether You Have a Design Team)

If your company has a professional design team and strong R&D capabilities, and can independently complete product design and innovation, then the OEM model would be a better choice. Through the OEM model, you can perfectly implement your design concepts and create products with unique competitive advantages.

Conversely, if you lack professional design talent and R&D resources, then the ODM model can help you quickly launch products and reduce initial operational risks. You can leverage the factory’s design capabilities to achieve rapid brand development.

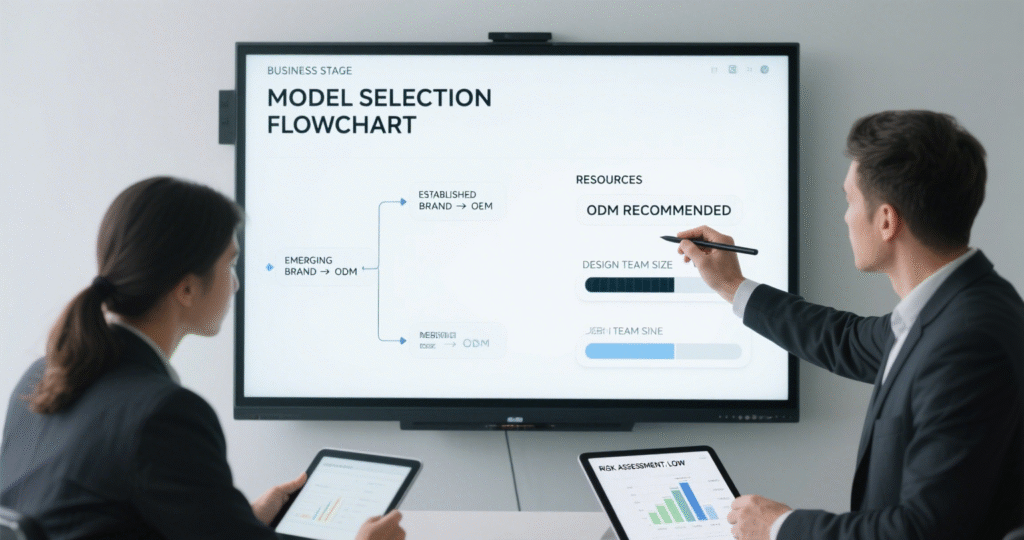

Based on brand stage

For startup brands with limited funds and resources and low brand awareness, choosing the ODM model can help you quickly launch products, capture market share, and accumulate brand experience. As the brand develops to a certain stage with established market foundations and financial strength, you can gradually transition to the OEM model to enhance the brand’s core competitiveness through independent design.

For mature brands, which typically have established design and R&D systems, the OEM model can better meet the brand’s personalized needs, maintaining its uniqueness and market leadership.

Based on budget considerations

If your budget is limited and you cannot afford the high costs of design teams and R&D, the ODM model can help you achieve product production and sales while controlling costs. If your budget is sufficient and you aim to build brand advantages through product differentiation, the OEM model, though requiring significant initial investment, is more beneficial for brand development in the long term.

Our company’s professional capabilities

Strong ODM design and R&D capabilities

Our company has years of experience in the ODM field of shapewear, having assembled a professional R&D team comprising senior designers, fabric experts, and process engineers. The team closely monitors market trends and changes in consumer demand, continuously introducing design solutions aligned with current trends.

In terms of fabric selection, we have established long-term partnerships with multiple renowned fabric suppliers, enabling us to provide customers with eco-friendly, comfortable, breathable fabrics that offer excellent shaping effects. In terms of manufacturing processes, we utilize advanced production technologies and equipment to ensure product quality and comfort.

Precise OEM Implementation Capabilities

We not only excel in the ODM field but also possess precise implementation capabilities in the OEM model. We have a comprehensive production management system and quality control processes, enabling us to strictly adhere to clients’ design requirements during production to ensure that every product meets their expectations.

We maintain close communication with clients, deeply understanding their design concepts and technical parameters. We strictly control every stage from sample production to mass production, promptly addressing any issues that arise during production to ensure timely, high-quality, and quantity-compliant delivery of products.

Both OEM and ODM cooperation models have their advantages and disadvantages. The choice of model primarily depends on your brand strength, development stage, and budget situation. Regardless of the model you choose, we can provide you with professional and efficient services.