How to Choose a Shapewear Supplier: 7 Criteria for B2B Buyers

To help you make an informed decision, we’ve compiled 7 critical criteria to evaluate when selecting a shapewear supplier.

For B2B buyers in the shapewear industry, choosing the right supplier isn’t just about finding a factory that can produce products—it’s about partnering with a partner that aligns with your brand’s quality standards, market positioning, and long-term growth goals. A poor supplier choice can lead to delayed shipments, inconsistent quality, or even compliance issues that damage your brand reputation. To help you make an informed decision, we’ve compiled 7 critical criteria to evaluate when selecting a shapewear supplier.

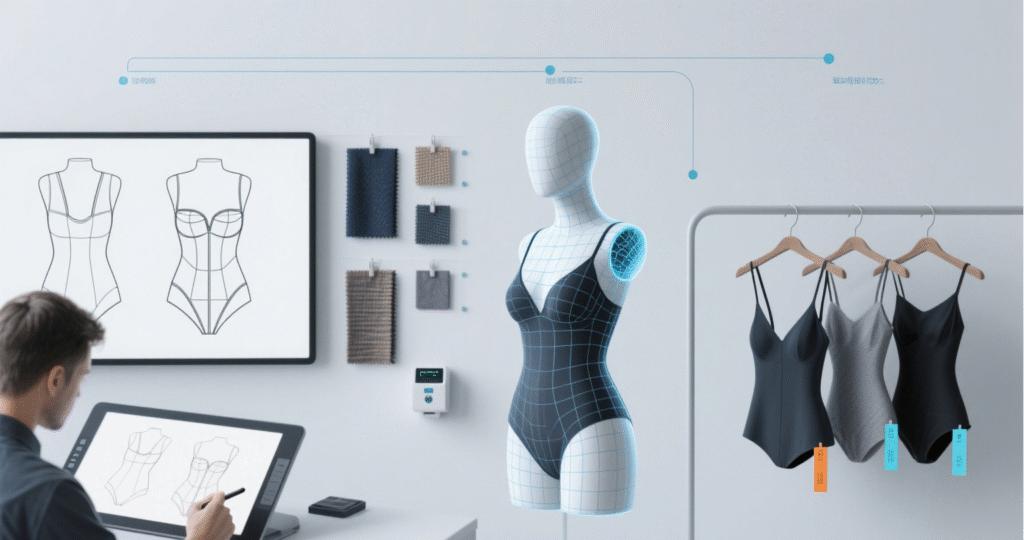

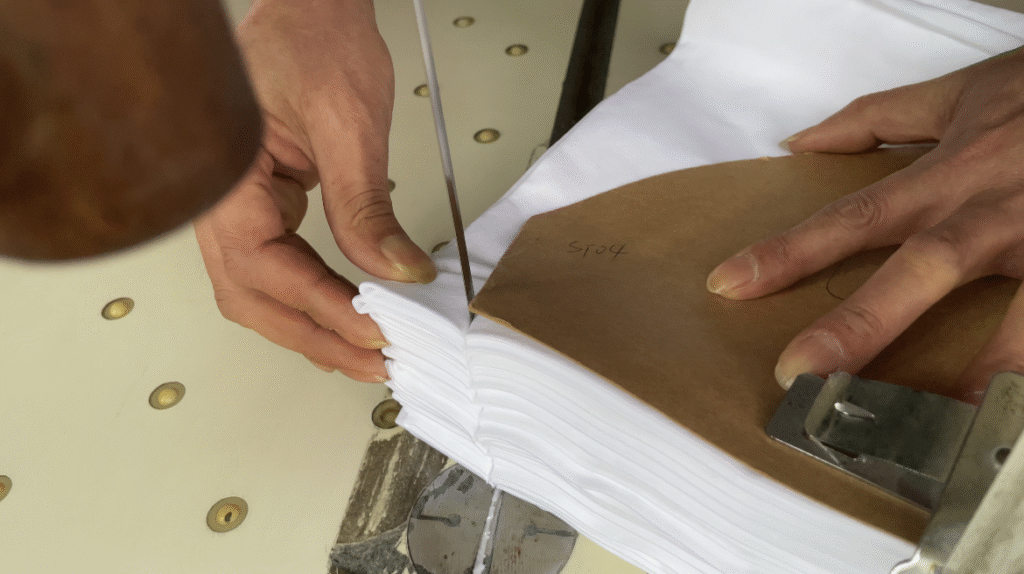

1. Product Quality & Consistency

Quality is non-negotiable in shapewear, where fit, durability, and comfort directly impact customer satisfaction (and return rates). A reliable supplier should have strict quality control (QC) processes at every stage—from fabric testing to final inspection.

2. Production Capacity & Lead Time

Nothing derails a product launch faster than missed deadlines. Evaluate a supplier’s production capacity to ensure they can meet your order volume—whether you need 1,000 units for a test run or 50,000 units for a seasonal push.

Key questions to ask:

- What’s your maximum monthly production capacity for shapewear?

- How do you handle peak season orders (e.g., before summer or holiday seasons)?

- What’s the typical lead time for custom orders vs. standard designs? A factory with in-house production (not outsourced) often has more control over lead times, as they avoid delays from third-party manufacturers.

A factory with in-house production (not outsourced) often has more control over lead times, as they avoid delays from third-party manufacturers.

3. Customization Capabilities (OEM/ODM)

In a competitive market, generic shapewear won’t help your brand stand out. B2B buyers increasingly need suppliers that offer OEM (Original Equipment Manufacturing) or ODM (Original Design Manufacturing) services to create unique products—whether it’s a custom fabric blend, exclusive sizing, or branded packaging.

Check if the supplier can:

- Adapt designs to your target market (e.g., European-fit vs. Asian-fit shapewear).

- Integrate new technologies (e.g., 3D body mapping for better fit).

- Accommodate small-batch custom orders (critical for testing new designs before scaling).

4. Compliance & Social Responsibility

Global retailers and brands face strict regulations—from product safety to ethical sourcing. A non-compliant supplier can lead to rejected shipments, fines, or consumer backlash.

Prioritize suppliers with:

- Clear documentation: Ask for compliance reports, factory audits, or third-party testing certificates to verify claims.

5. Supply Chain Stability

Shapewear production relies on consistent access to fabrics (like spandex-polyester blends), threads, and hardware. A supplier with a fragile supply chain risks delays if raw materials are out of stock.

Evaluate their supply chain by asking:

- Do you have long-term partnerships with fabric suppliers?

- How do you manage raw material shortages (e.g., backup suppliers for critical fabrics)?

- Can you share a supply chain contingency plan for unexpected disruptions (e.g., shipping delays)?

6. Cost Transparency & Fair Pricing

Price matters, but “cheap” often comes with hidden costs—like poor quality that increases return rates. A good supplier will explain their pricing structure (e.g., how material costs, labor, and order volume affect per-unit prices) instead of offering vague quotes.

Look for transparency in:

- Bulk pricing discounts (e.g., 5% off for orders over 10,000 units).

- Additional costs (e.g., custom mold fees for new designs, packaging upgrades).

- Payment terms (e.g., flexible terms for long-term partners).

Final Tip: Start Small, Then Scale

Once you’ve narrowed down suppliers, test the relationship with a small order. This lets you evaluate their communication, QC, and adherence to deadlines before committing to large volumes.

Choosing a shapewear supplier is a long-term investment. By prioritizing these 7 criteria, you’ll find a partner that not only delivers products but also supports your brand’s growth—whether you’re a startup retailer or an established global brand.