From Fabric to Craftsmanship: Unveiling the Full Production Process of High-Quality Yoga Apparel

From fabric selection to final product shipment, every stage is subject to rigorous standards, all to provide buyers with high-quality products. Let’s take a closer look at the production process and our factory’s quality control standards.

Table of content

| Fabric Selection: Controlling Quality from the Source |

| Cutting Stage: The Foundation of Precision |

| Sewing Process: Details Define Quality |

For buyers, selecting a yoga apparel factory with stringent quality control standards is crucial to ensuring product quality consistency and gaining market recognition. As a professional yoga apparel manufacturer, we fully understand the importance of quality control. From fabric selection to final product shipment, every stage is subject to rigorous standards, all to provide buyers with high-quality products. Let’s take a closer look at the production process and our factory’s quality control standards.

Fabric Selection: Controlling Quality from the Source

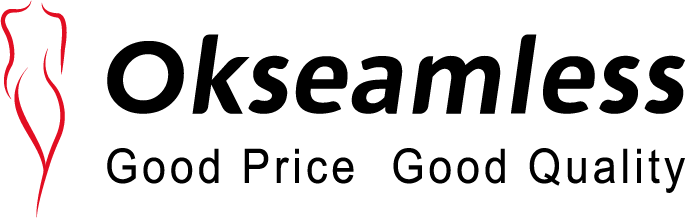

Fabric is the foundation of yoga apparel quality, and we have extremely strict standards for fabric selection to ensure product quality from the source.

When selecting fabric types, we choose appropriate fabrics based on the different styles and functional requirements of yoga apparel. For yoga apparel requiring high elasticity, we primarily use a blend of nylon and spandex, with nylon accounting for 85%–90% and spandex for 10%–15%. This fabric blend achieves an elastic recovery rate of over 85%, meeting the demands of various large-range movements in yoga practice. For styles that prioritize skin-friendly and breathable properties, we use a blend of combed cotton and spandex. The addition of combed cotton makes the fabric softer and more comfortable, while spandex ensures adequate elasticity.

To ensure fabric quality, we have established long-term stable partnerships with multiple renowned fabric suppliers. All fabrics must undergo rigorous testing before entering the factory. Testing includes fiber composition analysis, colorfastness testing, tensile strength testing, and abrasion resistance testing. Only fabrics that pass all testing can proceed to the next production stage.

Cutting Stage: The Foundation of Precision

Cutting is a critical stage in yoga apparel production, as its precision directly impacts subsequent sewing quality and the final garment’s wearability.

We utilize advanced automatic cutting equipment, which can control cutting errors to within 0.1 cm compared to traditional manual cutting, significantly enhancing cutting precision. Prior to cutting, technicians will layout the patterns on a computer based on the design drawings to optimize fabric usage and minimize fabric waste. Additionally, we conduct rigorous inspections of the cut fabric pieces to verify that their dimensions align with design specifications, edges are neat, and there are no defects. Any non-conforming pieces are immediately reworked to ensure that only qualified pieces proceed to the sewing stage.

Sewing Process: Details Define Quality

Sewing techniques are a key indicator of the quality of yoga apparel. We have established a series of stringent standards for the sewing process, paying meticulous attention to every detail.

Firstly, in terms of thread selection, we use high-strength nylon thread. This thread offers excellent elasticity and durability, ensuring it aligns with the fabric’s performance characteristics and preventing thread breakage during use. Second, we have established different standards for stitch density based on the type of fabric and the specific area being sewn. Generally, the stitch density at seams is 10–12 stitches per centimeter, ensuring both the durability of the seam and avoiding the loss of fabric elasticity that can result from overly dense stitching.

During the sewing process, we require workers to strictly follow process standards. For critical areas such as the waist, cuffs, and hem, we use double-stitching or reinforced stitching to enhance durability. Additionally, we regularly maintain and calibrate sewing equipment to ensure its proper functioning and maintain consistent sewing quality. Each yoga garment is inspected by quality control personnel after completion to check for smooth, secure stitching and any issues such as skipped stitches or missed seams.

Final Product Inspection: Strict Quality Control to Ensure Compliance

Final product inspection is the final step before yoga apparel is shipped from the factory. We implement a rigorous 100% inspection system to ensure that every piece of yoga apparel leaving the factory meets quality standards.

Quality control inspectors conduct a comprehensive inspection of the yoga apparel’s appearance, dimensions, fabric performance, sewing quality, and print/embroidery quality. For appearance, they check for stains, damage, color discrepancies, and other issues; for dimensions, they measure key areas such as garment length, bust circumference, and waist circumference to ensure compliance with design specifications; for fabric performance, they perform simple stretch tests to assess elastic recovery.

If any non-conforming products are identified, we will classify and handle them accordingly. For products that can be repaired, we will arrange for workers to perform rework and repairs; for products that cannot be repaired, we will dispose of them as scrap, ensuring that no non-conforming products enter the market.

From fabric selection to final product inspection, our factory adheres to strict quality control standards at every stage to produce high-quality yoga apparel. We believe that only superior quality can earn the trust of buyers and market recognition. If you are seeking a reliable yoga apparel supplier, consider us—we will support your business growth with high-quality products and professional services.